-

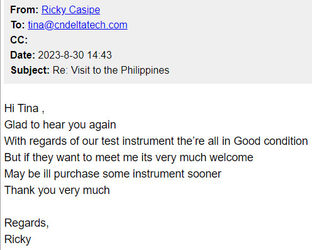

Mr. Ricky CasipeWith regards of our test instrument the’re all in Good condition. I'll purchase some instrument sooner. Thank you very much

Mr. Ricky CasipeWith regards of our test instrument the’re all in Good condition. I'll purchase some instrument sooner. Thank you very much -

Ms. Remy GalaponFrom year 2020 to 2023, we purchased more than 30 equipment from Delta Technology, they are all work well and the service from Delta Technology is also good.

Ms. Remy GalaponFrom year 2020 to 2023, we purchased more than 30 equipment from Delta Technology, they are all work well and the service from Delta Technology is also good. -

Mr. MilanThe VLF-80 Tester is perfect and thank you.

Mr. MilanThe VLF-80 Tester is perfect and thank you.

Far 25.853 Boeing Bss 7365 Aviation Materials Fire Test Equipment

| Place of Origin | China Mainland |

|---|---|

| Brand Name | Delta |

| Certification | ISO9001 |

| Model Number | FAR 25 |

| Minimum Order Quantity | 1 set |

| Price | USD1.0 / set |

| Packaging Details | Far 25.853 Boeing Bss 7365 Aviation Materials Fire Test Equipment is packed in plywood case. |

| Delivery Time | Within 30 days after the order is confirmed. |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 100 sets / month |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Reference Standards | 14 CFR 25.853 Part VI, Boeing Bss 7365, Aitm 2.005 | Radiant Panel Test Chamber | Stainless Steel |

|---|---|---|---|

| Radiant Heat Source | 400VAC 3 Phase Electric Heating Plate | Burner | Axisymmetric |

| Specimen Holders | 2 Sample Holders | Heat Flux Meter | 0 To 50 Kw/M2 |

| Equipment Type | Fire Testing Equipment | Data Process | Data Acquisition System, Window Software |

| Language | English | ||

| Highlight | Boeing Bss 7365 fire test equipment,aviation materials fire testing equipment,Far 25.853 fire test equipment |

||

FAR 25.853 Boeing BSS 7365 Fire Test Equipment for Aviation Materials

Introduction:

FAR 25.853 Boeing BSS 7365 Fire Test Equipment for Aviation Materials, by FAR Part 25 Appendix F Part VI, is designed to evaluate the flammability and flame propagation characteristics of thermal or acoustic insulation material used in an aircraft cabin when exposed to an electric radiant heat source and a defined flame source.

FAR 25.853 Fire Test Equipment consists of:

- The radiant panel test chamber is made of stainless steel and with an interior 0.5-inch refractory board. Consists of a glass viewing window, an internal chimney, and sliding tables.

- The radiant heat source is a 400VAC 3-phase electric heating plate with PID temperature control and a temperature control accuracy of 0.1 degrees.

- The radiant heat source is mounted in a frame with six 76mm wide radiant strips, the long side of which is perpendicular to the electric heating plate capable of withstanding an operating temperature of not less than 704 degrees.

- The radiation plate is placed in the test chamber at an angle of 30 degrees to the horizontal plane of the specimen.

- A pneumatic sliding table is provided to enable the user to achieve automatic control of the entry and exit of the specimen.

- The burner is an axisymmetric, 0.15mm aperture propane-air burner with a venturi pre-mix device.

- A movable burner (pneumatic drive) that allows the flame to be horizontal and at least 51 mm above the specimen plane.

- A thermocouple that can be inserted at the back of the case, 279mm from the back wall of the case, 292mm from the right side of the case wall, and located 51mm below the radiation plate, with an accuracy of 2 degrees.

- Water-cooled heat flux meter with a measurement range of 0 to 50 KW/m2, equipped with a self-circulating water cooling system.

- The calibration holding frame has three 25.4mm diameter jacks through the support plate, the center of the first jack being 191±3mm from the surface of the thermal radiation plate and the center of the two adjacent jacks being 51mm apart.

- Provides two specimen holders, 2 sample holders, one standard type, and one short type for hook and loop testing.

- Equipped with data acquisition system, and window software.

![]()