All Products

-

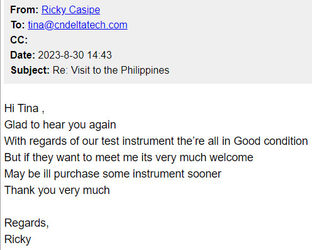

Mr. Ricky CasipeWith regards of our test instrument the’re all in Good condition. I'll purchase some instrument sooner. Thank you very much

Mr. Ricky CasipeWith regards of our test instrument the’re all in Good condition. I'll purchase some instrument sooner. Thank you very much -

Ms. Remy GalaponFrom year 2020 to 2023, we purchased more than 30 equipment from Delta Technology, they are all work well and the service from Delta Technology is also good.

Ms. Remy GalaponFrom year 2020 to 2023, we purchased more than 30 equipment from Delta Technology, they are all work well and the service from Delta Technology is also good. -

Mr. MilanThe VLF-80 Tester is perfect and thank you.

Mr. MilanThe VLF-80 Tester is perfect and thank you.

GWT Plastic Glow Wire Tester, Insulating Material Glow Wire Test Chamber

| Place of Origin | China |

|---|---|

| Brand Name | LAB TECH |

| Certification | ISO9001 |

| Model Number | GWT |

| Minimum Order Quantity | 1 set Plastic Glow Wire Tester |

| Price | USD1.0 |

| Packaging Details | GWT Plastic Glow Wire Tester packed in veneer case |

| Delivery Time | 45 days |

| Payment Terms | T/T, Western Union |

| Supply Ability | 10 sets per month |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Item Name | GWT Plastic Glow Wire Tester, Insulating Material Glow Wire Test Chamber | Function | For Insulating Material Flame Testing, Plastic Glow Wire Tester, Insulating Material Glow Wire Test Chamber |

|---|---|---|---|

| Application Field | Insulating Material, Plastic | Reference Standards | IEC 60695-2-10, UL 746A, IEC829, DIN695 |

| Temperature Range | 500 - 1000 Centigrade | Temperature Accuracy | ± 0.5 Centigrade |

| Temperature Sensor | USA OMEGA Brand 1mmK Armored Thermocouple | Timing Range | 0~99 S, ± 1s |

| Packing Mode | Veneer Case | Warranty Period | 1 Year |

| Service | Installation And Commissioning Service Is Available | ||

| Highlight | plastic glow wire tester,insulating material test chamber,fire testing equipment with warranty |

||

Product Description

Insulating Material Glow Wire Tester ---- Model GWT

Introduction:

- Electrical components or parts may reach very high temperature or even light the material nearby under failure or overload condition.

- Glow wire testing simulates thermal stress caused by glowing elements or overloaded resistors in short time, to evaluate the risk of fire.

- Glow wire test applies to electrical and electronic products, household appliance parts, plastic and non-metallic parts of insulating material, such as: switching shell relay socket.

- Test chamber and controller of glow-wire tester are part of integrated design, which is convenient for installation and debugging.

- Outshell of test chamber and important parts are made of stainless steel material and is smoke & gas corrosion resistance;

- Adopts thyristor control system to adjust current automatically;

- Time and temperature is digital display;

Reference Standards:

-

IEC60695-2-10;

-

UL 746A;

-

IEC829;

-

DIN695;

Specifications:

| 1 | Temperature Range | 500~1000℃, accuracy ± 0.5℃ |

| 2 | Temperature Sensor | USA OMEGA brand 1mmK armored thermocouple |

| 3 | Glow Wire Pressure on Sample | 0.95 n ± 0.1 n, 0.8 N~1.2 n, accuracy ± 0.1 n |

| 4 | Timing Range | 0~99 s, ± 1s |

| 5 | Ignited Bedding Layer | Min. thickness 10mm white pine board, 12g/M3~30g/M3 covering standard silk paper, away from the glow-wire 200mm ± 5mm |

| 6 | Relay | Omron |

| 7 | Circuit breaker | Schneider |

| 8 | Combustion Chamber | 0.75m³ |

| 9 | Hot Ring | Nickel-chromium wire(77% Ni/20±1% Cr), annealing treatment |

| 10 | Power supply | AC220V ± 10%/50Hz |

![]()

Recommended Products