-

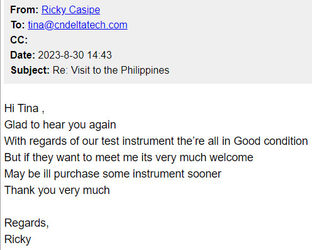

Mr. Ricky CasipeWith regards of our test instrument the’re all in Good condition. I'll purchase some instrument sooner. Thank you very much

Mr. Ricky CasipeWith regards of our test instrument the’re all in Good condition. I'll purchase some instrument sooner. Thank you very much -

Ms. Remy GalaponFrom year 2020 to 2023, we purchased more than 30 equipment from Delta Technology, they are all work well and the service from Delta Technology is also good.

Ms. Remy GalaponFrom year 2020 to 2023, we purchased more than 30 equipment from Delta Technology, they are all work well and the service from Delta Technology is also good. -

Mr. MilanThe VLF-80 Tester is perfect and thank you.

Mr. MilanThe VLF-80 Tester is perfect and thank you.

Transformer Dry Air Generator for Transformer Drying During Maintainence

| Place of Origin | Chongqing, China |

|---|---|

| Brand Name | Delta |

| Certification | ISO9001 |

| Model Number | GF |

| Minimum Order Quantity | 1 set |

| Price | USD1.0 / set |

| Packaging Details | Packed in wooden case and container |

| Delivery Time | Within 30 days after the order is confirmed |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 100 sets / month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | For Transformer Drying During Maintainence | Flow Rate | 50m3/H - 200m3/H |

|---|---|---|---|

| Working Pressure | 0.6-0.8MPa | Pressure Loss | <0.05 |

| Power Supply | 380V, 50Hz, 3 Phase 4 Wire | Total Power | 12kw - 26kw |

| Cooling Type | Wind | Oil Content In Air Outlet | 0.01ppm |

| Advantages | Reliable, Economic, Convenient And Safer | Control Method | Automatically Process Control |

| Material | Carbon Steel | Language | English |

| Delivery Lead Time | 20 Days | Shipping Method | By Sea |

| Service | Engineer Is Available For Oversea Service | ||

| Highlight | transformer dry air generator,transformer drying maintenance equipment,oil recycling air generator |

||

Movable Dry Air Generator for Transformer Drying During Maintainence

1. Introduction:

GF Series Dry Air Generator is suitable for supplying dry air which prevent the power equipment' inner parts from moisture during maintenance of transformer, reactor and other big power facilities. Meanwhile, Maintenance staff will not be short of oxygen working inside the equipment.

The Dry Air Compressor is more reliable, economic, convenient and safer than nitrogen.

Therefore, it can shorten maintenance period and improve the efficiency of maintenance quality

Parameters:

|

No. |

Parameter |

Unit |

||||

|

1 |

Flow Rate |

M3/H |

||||

|

2 |

Working Pressure |

Mpa |

||||

|

3 |

Pressure Loss |

Mpa |

||||

|

4 |

Pressure Drop |

Mpa |

||||

|

5 |

Noise |

Db(A) |

||||

|

6 |

Working Power |

kW |

||||

|

7 |

Total Power |

kW |

||||

|

8 |

Length |

cm |

||||

|

9 |

Width |

cm |

||||

|

10 |

Height |

cm |

||||

|

11 |

Weight |

kg |

||||

|

12 |

Discharge Pressure |

Mpa |

||||

|

13 |

Cooling Type |

Wind |

||||

|

14 |

Environment Temperature |

Temperature: -40ºC~45ºC, humidity≤90%, sea level≤4000m |

||||

|

15 |

Control Method |

Automatically process control and Gas compensation automatically |

||||

![]()

![]()

![]()

![]()